𝐀𝐠𝐢𝐥𝐞 𝐏𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐄𝐱𝐞𝐜𝐮𝐭𝐢𝐨𝐧

Quote from bsdinsight on 29 May 2025, 08:21📦 𝐁𝐫𝐢𝐝𝐠𝐢𝐧𝐠 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐲 & 𝐄𝐱𝐞𝐜𝐮𝐭𝐢𝐨𝐧 𝐢𝐧 𝐑𝐞𝐚𝐥-𝐓𝐢𝐦𝐞 𝐏𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐏𝐫𝐨𝐣𝐞𝐜𝐭𝐬

Recently, I’ve been leading a high-impact 𝐬𝐨𝐮𝐫𝐜𝐢𝐧𝐠 𝐚𝐧𝐝 𝐬𝐮𝐩𝐩𝐥𝐲 𝐜𝐨𝐨𝐫𝐝𝐢𝐧𝐚𝐭𝐢𝐨𝐧 initiative for a leading heavy equipment manufacturer. This real-world project has offered me deep insight into the practical application of 𝐬𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐩𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭, 𝐯𝐞𝐧𝐝𝐨𝐫 𝐚𝐥𝐢𝐠𝐧𝐦𝐞𝐧𝐭, and 𝐝𝐞𝐦𝐚𝐧𝐝-𝐬𝐮𝐩𝐩𝐥𝐲 𝐛𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 in a high-stakes environment.

Here are a few key learnings from the ground:

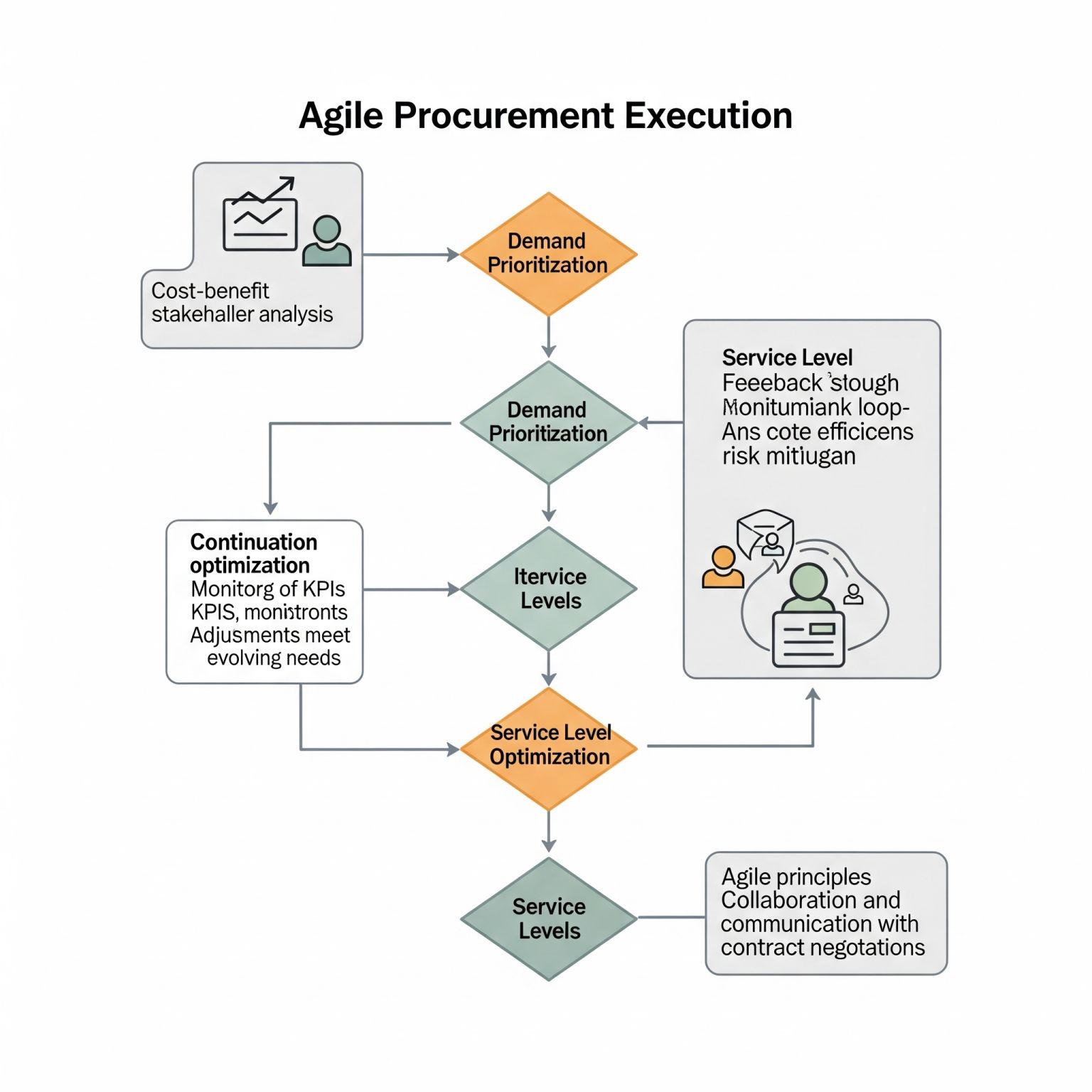

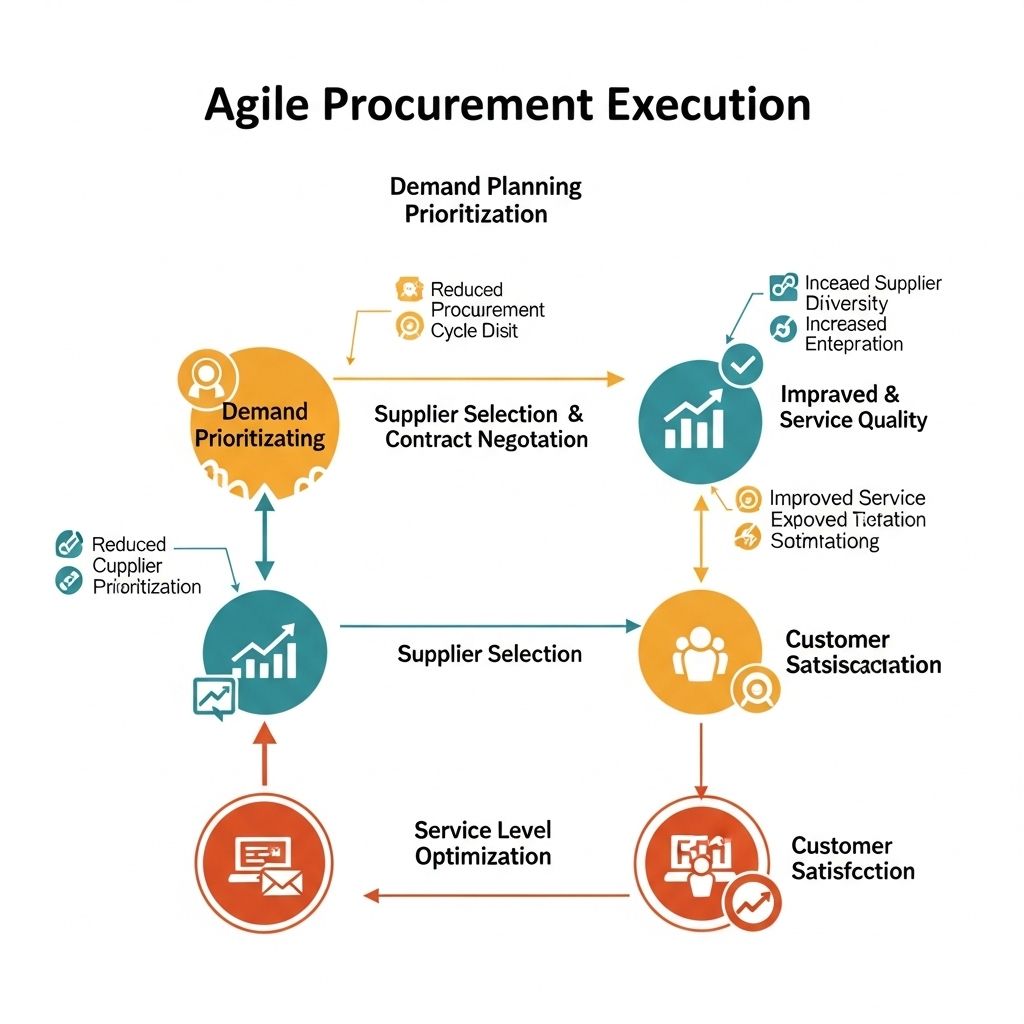

🔹 𝐀𝐠𝐢𝐥𝐞 𝐏𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐄𝐱𝐞𝐜𝐮𝐭𝐢𝐨𝐧: Managing expedited requirements pushed us to adopt an 𝐚𝐠𝐢𝐥𝐞 𝐩𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐦𝐨𝐝𝐞𝐥, focusing on reduced lead times, dynamic supplier response, and faster internal decision loops.

🔹 𝐃𝐞𝐦𝐚𝐧𝐝 𝐏𝐫𝐢𝐨𝐫𝐢𝐭𝐢𝐳𝐚𝐭𝐢𝐨𝐧 & 𝐒𝐞𝐫𝐯𝐢𝐜𝐞 𝐋𝐞𝐯𝐞𝐥 𝐎𝐩𝐭𝐢𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧: By collaborating with internal stakeholders, we identified priority materials based on production criticality and optimized service levels using a hybrid of 𝐀𝐁𝐂 𝐚𝐧𝐚𝐥𝐲𝐬𝐢𝐬 and 𝐝𝐞𝐦𝐚𝐧𝐝 𝐬𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧.

🔹 𝐂𝐨𝐥𝐥𝐚𝐛𝐨𝐫𝐚𝐭𝐢𝐯𝐞 𝐕𝐞𝐧𝐝𝐨𝐫 𝐌𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭: Timely vendor coordination played a crucial role. Leveraging 𝐕𝐌𝐈 (𝐕𝐞𝐧𝐝𝐨𝐫-𝐌𝐚𝐧𝐚𝐠𝐞𝐝 𝐈𝐧𝐯𝐞𝐧𝐭𝐨𝐫𝐲) practices informally, we created shared accountability for inventory flow and ensured 𝐎𝐓𝐈𝐅 (𝐎𝐧-𝐓𝐢𝐦𝐞 𝐈𝐧-𝐅𝐮𝐥𝐥) performance.

🔹 𝐃𝐢𝐠𝐢𝐭𝐚𝐥 + 𝐏𝐡𝐲𝐬𝐢𝐜𝐚𝐥 𝐒𝐲𝐧𝐞𝐫𝐠𝐲: Using SAP for 𝐌𝐑𝐏 (𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭𝐬 𝐏𝐥𝐚𝐧𝐧𝐢𝐧𝐠) and live data analysis helped us simulate supply scenarios, but on-ground supplier visits added a real-time layer to mitigate risk and accelerate output — a classic case of 𝐝𝐢𝐠𝐢𝐭𝐚𝐥-𝐩𝐡𝐲𝐬𝐢𝐜𝐚𝐥 𝐢𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧.

🔹 𝐑𝐢𝐬𝐤-𝐁𝐚𝐬𝐞𝐝 𝐏𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐀𝐩𝐩𝐫𝐨𝐚𝐜𝐡: Given the volatility and urgency, we applied a 𝐫𝐢𝐬𝐤-𝐭𝐢𝐞𝐫𝐞𝐝 𝐬𝐨𝐮𝐫𝐜𝐢𝐧𝐠 𝐬𝐭𝐫𝐚𝐭𝐞𝐠𝐲 to balance availability, cost, and vendor capacity, reducing supply-side uncertainty without inflating inventory.This project reinforced that successful supply chain execution isn’t just about processes — it’s about adaptability, data-informed decisions, and strong supplier collaboration.

📦 𝐁𝐫𝐢𝐝𝐠𝐢𝐧𝐠 𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐲 & 𝐄𝐱𝐞𝐜𝐮𝐭𝐢𝐨𝐧 𝐢𝐧 𝐑𝐞𝐚𝐥-𝐓𝐢𝐦𝐞 𝐏𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐏𝐫𝐨𝐣𝐞𝐜𝐭𝐬

Recently, I’ve been leading a high-impact 𝐬𝐨𝐮𝐫𝐜𝐢𝐧𝐠 𝐚𝐧𝐝 𝐬𝐮𝐩𝐩𝐥𝐲 𝐜𝐨𝐨𝐫𝐝𝐢𝐧𝐚𝐭𝐢𝐨𝐧 initiative for a leading heavy equipment manufacturer. This real-world project has offered me deep insight into the practical application of 𝐬𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐩𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭, 𝐯𝐞𝐧𝐝𝐨𝐫 𝐚𝐥𝐢𝐠𝐧𝐦𝐞𝐧𝐭, and 𝐝𝐞𝐦𝐚𝐧𝐝-𝐬𝐮𝐩𝐩𝐥𝐲 𝐛𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 in a high-stakes environment.

Here are a few key learnings from the ground:

🔹 𝐀𝐠𝐢𝐥𝐞 𝐏𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐄𝐱𝐞𝐜𝐮𝐭𝐢𝐨𝐧: Managing expedited requirements pushed us to adopt an 𝐚𝐠𝐢𝐥𝐞 𝐩𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐦𝐨𝐝𝐞𝐥, focusing on reduced lead times, dynamic supplier response, and faster internal decision loops.

🔹 𝐃𝐞𝐦𝐚𝐧𝐝 𝐏𝐫𝐢𝐨𝐫𝐢𝐭𝐢𝐳𝐚𝐭𝐢𝐨𝐧 & 𝐒𝐞𝐫𝐯𝐢𝐜𝐞 𝐋𝐞𝐯𝐞𝐥 𝐎𝐩𝐭𝐢𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧: By collaborating with internal stakeholders, we identified priority materials based on production criticality and optimized service levels using a hybrid of 𝐀𝐁𝐂 𝐚𝐧𝐚𝐥𝐲𝐬𝐢𝐬 and 𝐝𝐞𝐦𝐚𝐧𝐝 𝐬𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧.

🔹 𝐂𝐨𝐥𝐥𝐚𝐛𝐨𝐫𝐚𝐭𝐢𝐯𝐞 𝐕𝐞𝐧𝐝𝐨𝐫 𝐌𝐚𝐧𝐚𝐠𝐞𝐦𝐞𝐧𝐭: Timely vendor coordination played a crucial role. Leveraging 𝐕𝐌𝐈 (𝐕𝐞𝐧𝐝𝐨𝐫-𝐌𝐚𝐧𝐚𝐠𝐞𝐝 𝐈𝐧𝐯𝐞𝐧𝐭𝐨𝐫𝐲) practices informally, we created shared accountability for inventory flow and ensured 𝐎𝐓𝐈𝐅 (𝐎𝐧-𝐓𝐢𝐦𝐞 𝐈𝐧-𝐅𝐮𝐥𝐥) performance.

🔹 𝐃𝐢𝐠𝐢𝐭𝐚𝐥 + 𝐏𝐡𝐲𝐬𝐢𝐜𝐚𝐥 𝐒𝐲𝐧𝐞𝐫𝐠𝐲: Using SAP for 𝐌𝐑𝐏 (𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭𝐬 𝐏𝐥𝐚𝐧𝐧𝐢𝐧𝐠) and live data analysis helped us simulate supply scenarios, but on-ground supplier visits added a real-time layer to mitigate risk and accelerate output — a classic case of 𝐝𝐢𝐠𝐢𝐭𝐚𝐥-𝐩𝐡𝐲𝐬𝐢𝐜𝐚𝐥 𝐢𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧.

🔹 𝐑𝐢𝐬𝐤-𝐁𝐚𝐬𝐞𝐝 𝐏𝐫𝐨𝐜𝐮𝐫𝐞𝐦𝐞𝐧𝐭 𝐀𝐩𝐩𝐫𝐨𝐚𝐜𝐡: Given the volatility and urgency, we applied a 𝐫𝐢𝐬𝐤-𝐭𝐢𝐞𝐫𝐞𝐝 𝐬𝐨𝐮𝐫𝐜𝐢𝐧𝐠 𝐬𝐭𝐫𝐚𝐭𝐞𝐠𝐲 to balance availability, cost, and vendor capacity, reducing supply-side uncertainty without inflating inventory.

This project reinforced that successful supply chain execution isn’t just about processes — it’s about adaptability, data-informed decisions, and strong supplier collaboration.