Forum breadcrumbs – You are here:ForumChuyên ngành BSD cung cấp: Chuyên ngànhSản xuấtWhy Manufacturing Businesses Need …

Why Manufacturing Businesses Need an ERP System for Streamlined Operations

bsdinsight@bsdinsight-com

837 Posts

#1 · 6 April 2025, 11:14

Quote from bsdinsight on 6 April 2025, 11:14In today’s fast-moving and highly competitive market, manufacturing businesses face numerous operational challenges. From managing complex supply chains to meeting tight deadlines and ensuring quick product deliveries, efficiency is the key to success. This is why many manufacturers turn to ERP (Enterprise Resource Planning) systems—to work smarter, optimize operations, and stay ahead of the competition.By providing businesses with the tools and insights they need, Manufacturing ERP software empowers organizations to thrive in this demanding environment. But the real question is: How can your business not just keep up but truly stand out? The answer lies in embracing technology to enhance operations. With tools like ERP systems, businesses don’t just survive—they grow.The Challenges in ManufacturingManufacturing businesses operate in a dynamic environment where delays, inefficiencies, and miscommunication can result in significant losses. Some of the key challenges include:

In today’s fast-moving and highly competitive market, manufacturing businesses face numerous operational challenges. From managing complex supply chains to meeting tight deadlines and ensuring quick product deliveries, efficiency is the key to success. This is why many manufacturers turn to ERP (Enterprise Resource Planning) systems—to work smarter, optimize operations, and stay ahead of the competition.

By providing businesses with the tools and insights they need, Manufacturing ERP software empowers organizations to thrive in this demanding environment. But the real question is: How can your business not just keep up but truly stand out? The answer lies in embracing technology to enhance operations. With tools like ERP systems, businesses don’t just survive—they grow.

The Challenges in Manufacturing

Manufacturing businesses operate in a dynamic environment where delays, inefficiencies, and miscommunication can result in significant losses. Some of the key challenges include:

-

Supply Chain Management

ERP systems integrate all aspects of the supply chain, from procurement to distribution, ensuring real-time visibility, reducing bottlenecks, and enhancing decision-making. This allows businesses to track inventory, optimize logistics, and respond proactively to disruptions.

-

Production Scheduling

Managing machinery, labor, and materials without the right tools can be overwhelming. A reliable production scheduling software—often integrated within an ERP system—simplifies this process, optimizes resource allocation, and ensures deadlines are met efficiently.

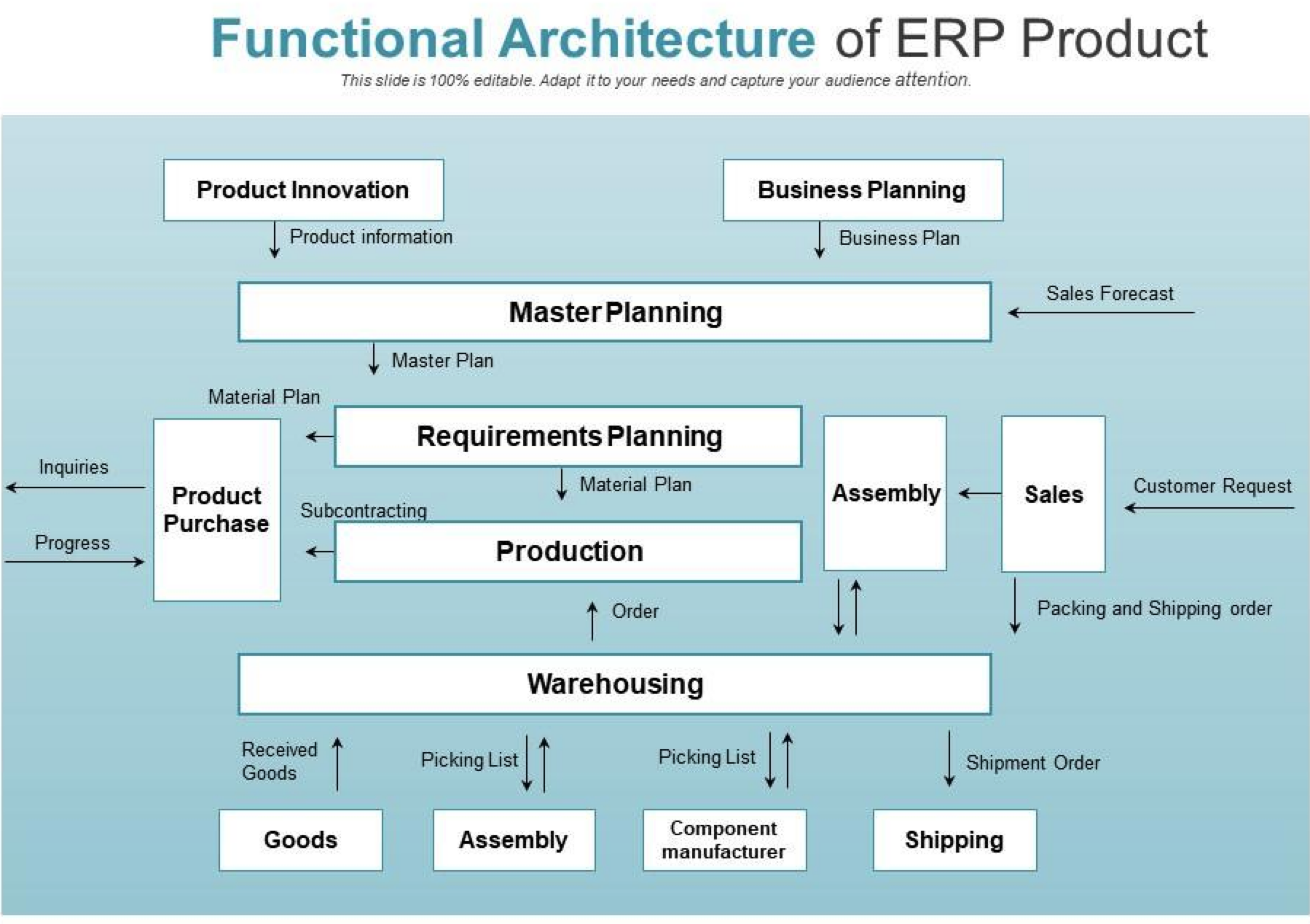

The Role of ERP in Manufacturing Resource Planning (MRP)

Manufacturing Resource Planning (MRP) is central to efficient manufacturing operations. ERP systems take MRP to the next level by integrating it with other essential business functions such as finance, human resources, and customer relationship management. This creates a unified platform that fosters collaboration and improves efficiency.

For example, if there is a sudden spike in demand, coordinating production across departments without an ERP system can be chaotic. With an ERP system in place, businesses can seamlessly adjust production schedules, allocate resources effectively, and monitor inventory levels in real-time.

Automating Business Processes for Efficiency

Manual processes often hold businesses back, particularly in today’s digital world. Business process automation, a key feature of modern ERP systems, enables manufacturers to:

-

Automate repetitive tasks

-

Reduce human errors

-

Improve overall efficiency

By automating tasks such as invoicing and quality control, ERP systems allow businesses to focus on strategic priorities rather than routine operations. For instance, automated data entry ensures accurate inventory levels, preventing both overstocking and stockouts. This not only saves costs but also enhances customer satisfaction by ensuring timely order fulfillment.

Gaining a Competitive Edge with ERP Systems

In a rapidly evolving market, manufacturing businesses cannot afford inefficiencies. ERP systems provide a competitive advantage by offering:

-

Real-time insights for informed decision-making

-

Predictive analytics to foresee potential challenges

-

Advanced reporting capabilities to enhance strategic planning

For instance, supply chain management ERP tools can anticipate disruptions and suggest alternative suppliers or routes, ensuring smooth operations. Similarly, production scheduling software optimizes workflows to meet tight deadlines without compromising quality.

The Future of Manufacturing with ERP

As technology advances, ERP systems are evolving with the integration of cutting-edge technologies such as:

-

Internet of Things (IoT) for real-time data collection

-

Artificial Intelligence (AI) and Machine Learning for predictive maintenance and demand forecasting

-

Automation and Smart Decision-Making to further enhance efficiency

These innovations are paving the way for smarter, more efficient manufacturing processes, ensuring businesses remain agile and competitive.

Conclusion

To overcome operational challenges and achieve sustainable growth, manufacturing businesses must embrace ERP systems. Whether it’s supply chain management, production scheduling, or business process automation, these tools are indispensable for modern manufacturers. By investing in manufacturing resource planning and comprehensive business software, companies can streamline operations, reduce costs, and deliver exceptional value to their customers.

The future belongs to those who adapt, and for manufacturing businesses, ERP systems are the key to staying relevant and thriving in an ever-changing landscape.

Click for thumbs down.0Click for thumbs up.0